Deskripsi Produk

Jalur produksi tabung / lembaran isolasi busa karet Huashida menggunakan teknologi mutakhir,khusus dirancang untuk memproduksi bahan isolasi busa karet berkualitas tinggi (juga dikenal sebagai "pipa spons" atau "pipa isolasi karet-plastik")Dilengkapi dengan sistem kontrol otomatis dan memanfaatkan teknologi inti eksklusif, lini kami mengintegrasikan komponen premium untuk memastikan efisiensi produksi yang superior dan kinerja produk.

Jalur produksi canggih ini secara efisien memproduksi isolasi busa karet dari kombinasi karet akrilonitril-butadien (NBR), polivinil klorida (PVC), dan bahan tambahan berkualitas tinggi.Proses ini menggunakan teknik ekstrusi dan busa yang canggih dan sepenuhnya bebas dari CFC, menunjukkan komitmen kuat kami terhadap tanggung jawab lingkungan.

Jalur kami terutama memproduksi isolasi dalam dua bentuk:

Tabung Isolasi busa karet: Ideal untuk mengisolasi pipa.

Lembar Isolasi busa karet: Sempurna untuk mengisolasi permukaan datar atau wadah.

Fitur

Bahan isolasi yang diproduksi di jalur kami membanggakan serangkaian sifat luar biasa yang komprehensif:

Fleksibilitas yang Luar Biasa: Lembut, sangat lentur, dan mudah dipasang, beradaptasi dengan geometri yang kompleks.

Ketahanan Termal: Mempertahankan kinerja yang stabil di berbagai suhu, menawarkan ketahanan dingin dan panas yang sangat baik.

Keamanan yang Ditingkatkan: Menampilkan tahan api yang unggul.

Perlindungan Kelembaban: Memiliki karakteristik tahan air dan kelembaban yang kuat, menjaga efektivitas isolasi.

Efisiensi Energi: Memiliki konduktivitas termal rendah, secara signifikan mengurangi kehilangan panas atau keuntungan.

Pengurangan Kebisingan & Getaran: Berkontribusi untuk lingkungan yang lebih tenang dengan menyerap kejut dan suara.

Aplikasi

Spektrum Aplikasi yang Luas

Bahan isolasi busa karet kami banyak digunakan di berbagai industri penting, secara efektif meminimalkan limbah energi dari fluktuasi suhu:

Fasilitas Industri: Penting untuk isolasi termal pipa, wadah, dan berbagai peralatan pengolahan.

HVAC & Kontrol Iklim: Penting untuk isolasi pipa dan peralatan di sistem pendingin udara pusat dan pemanasan/pendingin, secara signifikan mengurangi kerugian energi.

Konstruksi: Menyediakan isolasi yang handal untuk saluran pasokan air dingin/panas dan pipa sistem pemanas.

Akustik & Vibration Damping: Digunakan sebagai lapisan pada bagian mesin atau peralatan untuk mengurangi kebisingan dan getaran yang efektif.

Berbagai Sektor: Ditemukan di industri kimia, farmasi, tekstil, metalurgi, pembuatan kapal, kendaraan, dan peralatan.Juga digunakan dalam produk khusus seperti pegangan kelas tinggi / lengan untuk kebugaran dan peralatan medis, dan untuk pipa indoor/outdoor di sistem pemanasan surya.

Jalur produksi kami yang canggih terdiri dari peralatan penting yang memastikan produksi yang terus menerus dan otomatis:

Pemotong karet: Untuk persiapan bahan baku yang tepat.

Mixer internal: Memastikan pencampuran karet dan senyawa tambahan secara menyeluruh.

Lift ember: Memfasilitasi transfer bahan yang efisien.

Open Mill: Mengolah bahan untuk meningkatkan seragam dan plastisitas.

Rubber Extruder: Membentuk bahan campuran menjadi tabung atau lembaran.

Transition Roller: Memandu bahan dengan lancar ke tahap pemanasan.

Infrared Foaming Stove: Memulai proses foaming dengan panas terkontrol.

Hot Air Foaming Stove: Mengakhiri busa seragam, membangun struktur insulasi yang berpori.

Traktor dan Peralatan Pemotongan Otomatis: Menyediakan menarik yang stabil dan pemotongan produk akhir yang tepat.

Mengapa Memilih Jalur Produksi Kami?

√ Investasi di Huashida Rubber Foam Insulation Tube/Sheet Production Line menawarkan keuntungan yang jelas:

√ Teknologi Terbaru & Produksi Kontinyu Otomatis Penuh: Pengalaman produksi tanpa batas, volume tinggi.

√ Kinerja superior: lini kami melampaui kemampuan sistem yang sebanding dalam aspek utama.

√ Kontrol Suhu Otomatis & Konsumsi Energi Rendah: Mencapai efisiensi optimal dan mengurangi biaya operasi melalui manajemen proses cerdas.

Profil Perusahaan

Qingdao Huashida Machinery Co., Ltd didirikan pada tahun 2003. sejak awal, Huashida telah berfokus pada pipa isolasi poliuretan plastik jalur produksi, jalur produksi pipa anti korosi 3PE, diameter besar jalur produksi pipa bawah tanah dan sendi pipa plastik selama 20 tahun. Kami selalu memberikan pentingnya penelitian dan pengembangan,bekerja sama erat dengan Universitas Beijing teknologi kimia, Universitas Teknologi Qingdao dan lembaga penelitian ilmiah. dengan menyerap teknologi canggih di dalam dan luar negeri,setelah 20 tahun usaha kami sekarang peringkat salah satu dari 3 produsen teratas di industri di CinaMesin Huashida telah diterima dengan baik di Arab Saudi, Kazakhstan, Uzbekistan, Uni Emirat Arab, Turki, Rusia, dll.

Pameran

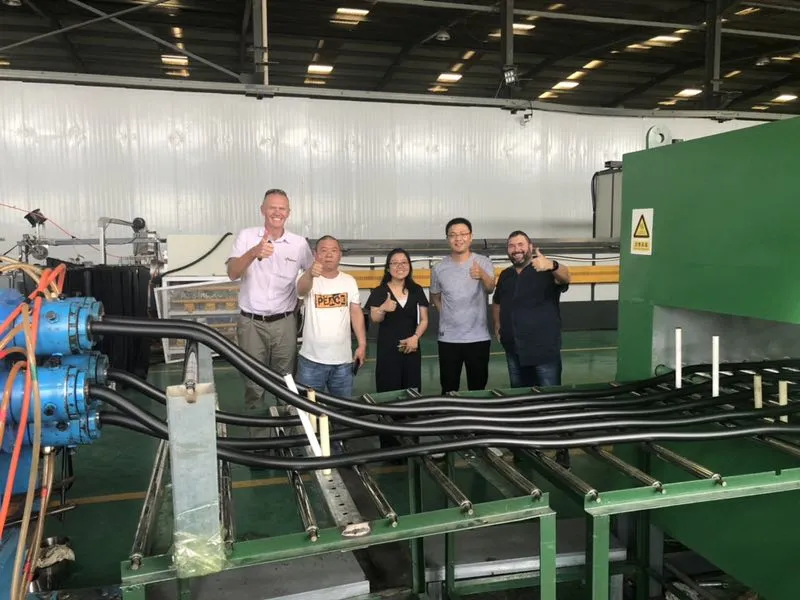

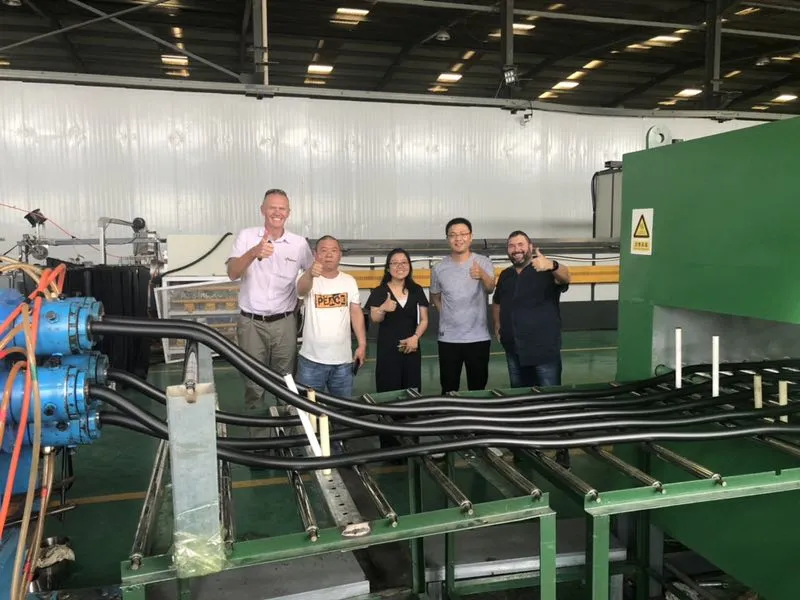

klien

kemasan

Sertifikasi

Pesan Anda harus antara 20-3.000 karakter!

Pesan Anda harus antara 20-3.000 karakter! Silakan periksa email Anda!

Silakan periksa email Anda!  Pesan Anda harus antara 20-3.000 karakter!

Pesan Anda harus antara 20-3.000 karakter! Silakan periksa email Anda!

Silakan periksa email Anda!